Water & Wastewater Parameters

-

Biomass Methane Potential

-

BTEX (Oil in Water)

-

Conductivity / TDS / Salinity

-

Dissolved Oxygen

-

E. Coli & Total Coliforms

-

Free Chlorine, Total Chlorine & Chloramine (Monochloramine)

-

Greenhouse Gas (N2O)

-

Hydrostatic Level

-

Microbial Monitoring

-

MLSS / TSS (Suspended Solids & Total Solids)

-

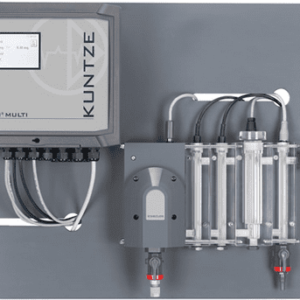

Nitrite, Nitrate, Ammonia, Free Ammonia, Ortho-phosphate, Sulphite, Manganese, UV254, Colour / Hazen

-

pH / ORP

-

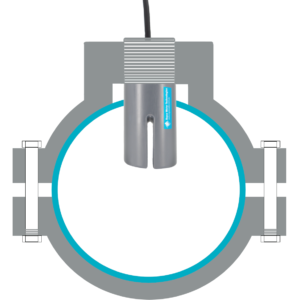

Royce Dissolved Oxygen

-

Royce Hydrostatic Level Sensor

-

Royce MLSS

-

Sludge Blanket / Bed Level Interface

-

Total Nitrogen, Total Phosphorus, COD, BOD, TOC, DOC, UV254, Colour / Hazen

-

Turbidity

-

Water Autosamplers

-

Water Moving Aeration